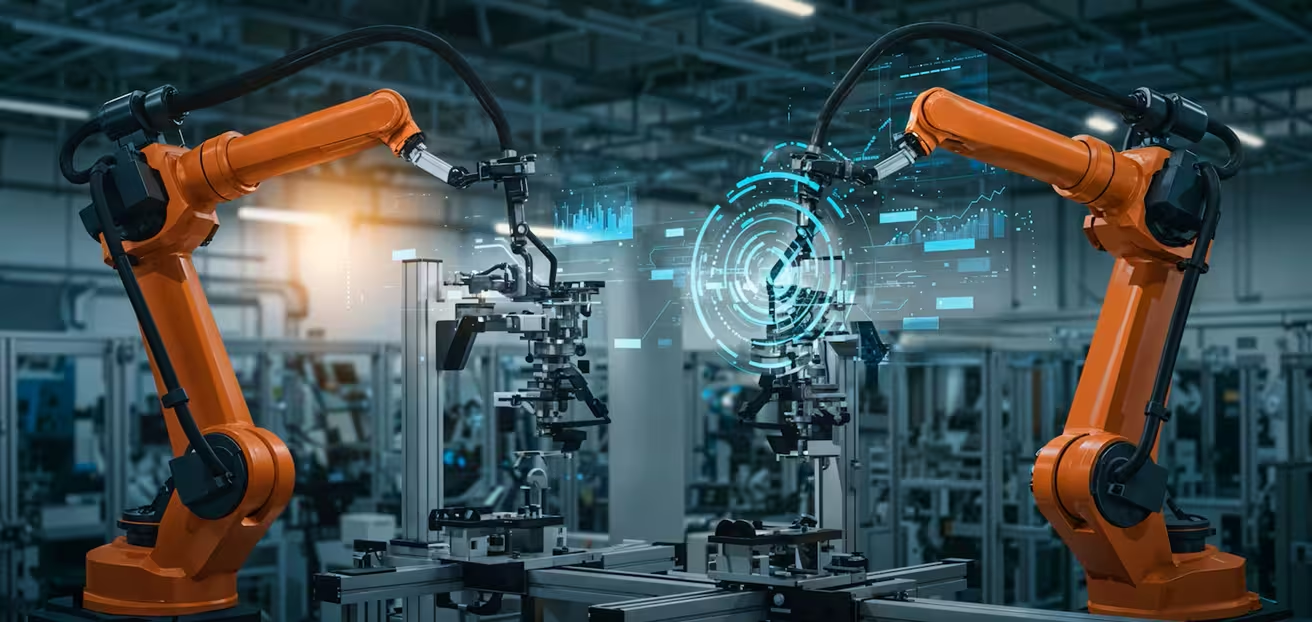

Efficiency Through Automation

Manual processes are slow, error-prone, and costly. We automate your manufacturing lines and industrial processes using state-of-the-art control systems, PLCs, and SCADA solutions.

Our goal is to maximize your throughput, improve safety, and ensure consistent quality, allowing your workforce to focus on higher-value tasks.

Automation Solutions

PLC Programming

Expert logic design for Siemens, Allen-Bradley, and Mitsubishi controllers to orchestrate complex machinery.

SCADA & HMI

Intuitive Human-Machine Interfaces and supervisory systems for real-time process visualization and control.

Robotics Integration

Seamless integration of industrial arms and cobots for pick-and-place, welding, and assembly tasks.

Motion Control

Precise servo and stepper motor control systems for high-speed, high-accuracy applications.

Technology Stack

We deliver robust automation solutions using industry-leading hardware and software.

PLC & Controllers

Siemens S7-1200/1500, Allen-Bradley ControlLogix, Mitsubishi FX Series

SCADA & HMI

Ignition, Wonderware, WinCC, Rockwell FactoryTalk

Robotics

FANUC, KUKA, Universal Robots (Cobots), ABB

Industrial Networks

PROFINET, EtherNet/IP, Modbus, OPC UA, IO-Link

Automation Project Lifecycle

- 1System Design:Creating electrical schematics and control logic flowcharts.

- 2Hardware Assembly:Panel wiring, sensor installation, and network cabling.

- 3Programming:Developing PLC logic (Ladder, Structured Text) and HMI screens.

- 4Commissioning:On-site testing, SAT (Site Acceptance Test), and operator training.

Industry Applications

Why Automate?

Consistency

Machines don't get tired. Ensure every product meets the exact same standard, 24/7.

Safety

Remove humans from hazardous environments and let automated systems handle the risk.